Computer vision in manufacturing: 9 use cases, examples, and best practices

May 23, 2023

- Home

- Computer vision in manufacturing

Head of AI/ML Center of Excellence

Computer vision (CV) in manufacturing involves AI-powered systems that can capture, analyze, and understand visual inputs from the physical world (such as factories and other industrial sites) to help humans take proper actions and assist them in various production processes.

Rely on Itransition's computer vision consulting and implementation services to fully seize the benefits of this technology in your business scenario.

Computer vision in manufacturing: a market overview

Computer vision technology and the manufacturing sector look set to develop closer ties in the years to come.

of manufacturers consider computer vision important for meeting their business goals

IBM, 2021

of the global computer vision market is covered by its industrial segment alone

Grand View Research, 2021

CV market CAGR 2023-2030, with manufacturing as one of its fastest-growing segments

Mordor Intelligence, 2023

Cybersecurity

Advanced data analytics including predictive/prescriptive analytics

Automation/robotics

IIoT/IoT data from devices

Artificial intelligence (AI) and machine learning (ML)

Computer vision

Autonomous systems

Augmented/virtual/mixed reality

Next generation ERP systems

Track and trace for supply chain visibility

Scheme title: Top 10 technologies helping manufacturers meet their business goals

Data source: ibm.com — 2021 Digital transformation assessment Covid-19: a catalyst for change

Step up your productivity with Itransition's computer vision solutions

An example of a manufacturing-oriented computer vision system

A study by the Institute of Electrical and Electronics Engineers suggested a potential system framework to integrate computer vision into your existing manufacturing environment. These are its key components and related processes:

Scheme title: Main components of a computer vision system for manufacturing

Data source: IEEE — Computer vision techniques in manufacturing, 2022

Lighting module

Provides the sensing module with uniform illumination and enables it to capture clear images of the manufacturing system.

Manufacturing system

Encompasses assembly lines, assembly robots, and automated guided vehicles.

Sensing module

Comprises cameras that collect visual data from the manufacturing system and send it to the CV system via the Internet of Things (IoT).

Computer vision system

Typically powered by machine learning (ML) algorithms, it can perform different tasks from product counting to execution quality control with defect (anomaly) detection.

Decision-making module

Processes the previous results with rule-based or more complex artificial intelligence algorithms to trigger a suitable course of action.

Actuator

A set of robots that interact with the manufacturing system according to the strategies defined by the decision-making module.

9 use cases of computer vision in manufacturing

Computer vision systems can be deployed in many use cases and operational scenarios within manufacturing processes.

1 Quality inspection

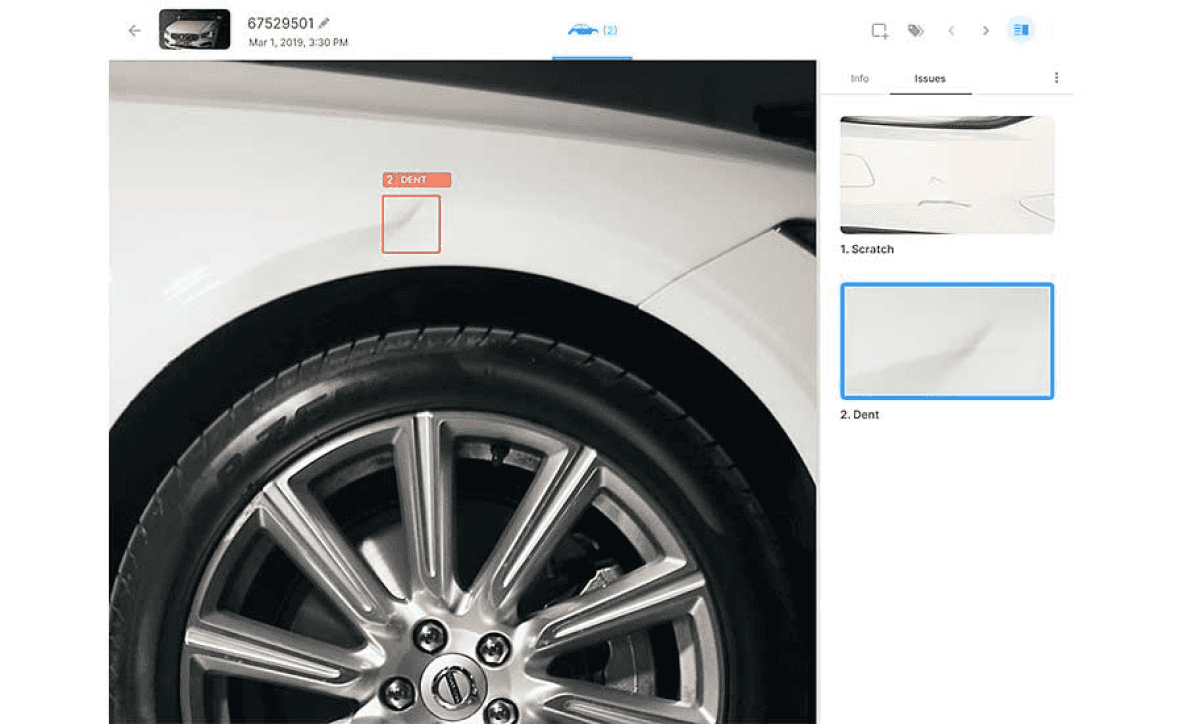

Combined with ML-powered anomaly detection, computer vision enables automated visual inspection to identify defective products with any type of anomaly (e.g. scratches or dents).

2 Assembly process automation

3 Packaging inspection

4 Object detection and recognition

5 Compliance monitoring

6 Sorting and counting

7 Dimensional measurement

8 3D vision and design

9 Supply chain traceability

Seize the business opportunities unlocked by computer vision

Examples of computer vision in manufacturing

Here are a few real-life examples of manufacturing companies leveraging computer vision in a variety of processes:

US-based hardwood & plywood manufacturer

Dow Chemical

Volvo

Image title: Volvo Cars’ visual inspection system Atlas

Data source: assemblymag.com—AI-based vision technology aids vehicle inspection

Komatsu

Tennplasco

Benefits of computer vision in manufacturing

The adoption of computer vision systems in industrial processes can strengthen the manufacturing sector in terms of:

Greater productivity

According to Deloitte, adopting computer vision, automation, and other smart factory initiatives accelerates manufacturing cycles, resulting in a 12% growth in labor productivity and 10% in total production output.

Cost optimization

Increased productivity and minimized machine downtime via automation and computer vision-based maintenance (up to 50%, based on McKinsey's estimates) translate into a general reduction in operating costs.

Improved quality

Computer vision-driven robots operate with surgical precision, ensuring better product quality, minimized human error, and an overall reduction of 10-20% in QA operations cost, as reported by McKinsey.

Workforce safety

Deloitte highlighted that computer vision systems in manufacturing enable organizations to identify dangerous malfunctions, monitor workers' conditions, and detect any sign of fatigue or discomfort.

Computer vision adoption roadmap for manufacturers

Implementing an ML-based computer vision solution in a manufacturing scenario will involve business-oriented and technical steps. Here’s a brief rundown of the main adoption stages.

1

Business needs analysis

Analyze customer business needs and expectations

Assess the current tech ecosystem

Frame corporate needs and goals

Define the solution’s scope and requirements

2

Initial data analysis

Map and assess corporate data sources

Identify external data sources (public databases, etc.)

3

Solution design

Design the solution’s architecture

Set up a project plan, including budget and timeline

Identify a suitable tech stack

Define the scope of a PoC, if required

4

Building the solution

Perform data cleansing, annotation, and transformation

Define the solution’s assessment criteria

Process data with algorithms

Build a CV model trained to recognize patterns

5

Integration and rollout

Integrate the CV model into the solution

Deploy the product in the target environment

6

Support

Fine-tune the CV model with new data

Perform ongoing maintenance, updates, and fixes

Computer vision adoption challenges and best practices

When implementing computer vision in manufacturing, you can face some technical challenges. Keep in mind the following recommendations to streamline its adoption.

Integration

Integration

Processing

Processing

Security

Security

A journey towards Industry 4.0

Along with other technologies driving digital transformation in manufacturing and the shift towards the Industry 4.0 model, computer vision proved to be a valuable ally for this sector. Indeed, its implementation has often resulted in significant cost cuts, superior quality control, higher production output, and increased worker safety.

To reap the full benefits of this technology, however, companies will need an upgraded tech ecosystem, a solid data management and integration strategy, and the expert guidance of a trusted partner like Itransition.

Need help with implementing a CV-driven solution?

FAQs

How is computer vision used in manufacturing?

Computer vision systems cover various use cases and operational scenarios. These include, for example, product design, automated product assembly, quality inspection, predictive maintenance, inventory management, supply chain traceability, and safety monitoring.

How reliable are computer vision systems in manufacturing?

Thanks to modern deep learning algorithms and neural networks, computer vision systems for object or anomaly detection and other manufacturing-related tasks have achieved close to 99% accuracy, as reported by SAS.

What is the difference between computer vision and machine vision?

While they partially overlap, computer and machine vision diverge in terms of focus.

- Computer vision

represents a broader field that includes tools and techniques to capture, process, and understand visual inputs for both analytical and practical purposes. However, the emphasis is on advanced cognitive skills, data analytics, and decision-making. - Machine vision

is a more specific term referring to the use of vision systems for industrial or manufacturing applications, including inspection, quality control, and automation. Machine vision uses specialized hardware and software to capture and analyze visual data in real time, such as measuring dimensions, detecting defects, and identifying patterns.

Case study

A furniture manufacturing software suite

Read the story behind Itransition’s 5-year collaboration with a leading UK furniture manufacturer on web, mobile and VR solutions.

Insights

Machine learning in manufacturing: key applications, examples & adoption guidelines

Learn how machine learning can help manufacturers to improve operational efficiency, discover real-life examples, and learn when and how to implement it.

Insights

ERP for manufacturing: end-to-end solution overview

Explore the core functionality, benefits, and challenges of ERP for manufacturing, along with adoption guidelines and top platforms available on the market.