Services

SERVICES

SOLUTIONS

TECHNOLOGIES

Industries

Insights

TRENDING TOPICS

INDUSTRY-RELATED TOPICS

OUR EXPERTS

Our customer needed to enable 100% inspection of the produced medical packaging’s coating to comply with their end-clients’ quality standards. We delivered a custom computer vision solution to analyze photos of medical container surfaces under magnification, helping the customer achieve consistent, all-around inspection of their products without any manual effort.

Convolutional neural networks

Vision transformers

Semantic segmentation models

Our customer is a US-based manufacturer of various containers used for safe handling and storage of medical items. The company supplies its products to both public and private laboratories, clinics, and hospitals across the country.

Industry

Manufacturing

Location

USA

Services

Medical container production

Client base

1,500+ healthcare institutions

To verify the quality of medical packaging coating, including its thickness and coverage, the customer manually analyzed selected products from each batch, which didn’t allow them to ensure total coating examination. Due to this, they couldn’t expand and work with organizations whose compliance policies required 100% inspection. In light of this, they approached Itransition to help them achieve complete product quality inspection coverage.

We delivered an AI-powered solution for accurate and quick detection of defects on the surfaces of medical containers to ensure 100% quality inspection, deploying it to the customer’s on-premises environment for uninterrupted operation.

We started our collaboration by visiting the customer’s plant to study their current manufacturing and coating inspection processes, IT infrastructure, and defect validation requirements and guidelines.

Based on our findings, we conceptualized a computer vision solution powered by neural networks. Aiming for non-disruptive production pipeline adjustments, we suggested enabling AI detection at the final production process stage with the help of a high-magnification camera that would capture container images and send them for analysis to the AI solution. Depending on the results, the container would be either approved for shipment or deemed defective.

One of the key project requirements was ensuring that the AI model could segment coating areas based on coating quality. To enable this, we worked with the customer to prepare a dataset containing about 1,000 labeled images to properly train the AI model. Moreover, we established a pipeline for automatic model retraining so that it learns based on live data over time, adapting its outcomes without human intervention.

We divided the solution deployment process into several stages. Initially, we launched the AI solution across all production lines to run in parallel with the existing defect detection workflow so we could observe its operation. We analyzed and validated the system’s output for each image, such as whether a defect was detected, whether there were no defects, and where the defect was found, and retrained the solution based on identified edge cases to have it meet the expected accuracy threshold.

After going through three review and retrain cycles, we managed to achieve 99.3% system accuracy, which we verified using 10,000 products. Finally, we received approval from the quality control department to put the system into full operation,replacing the previous process.

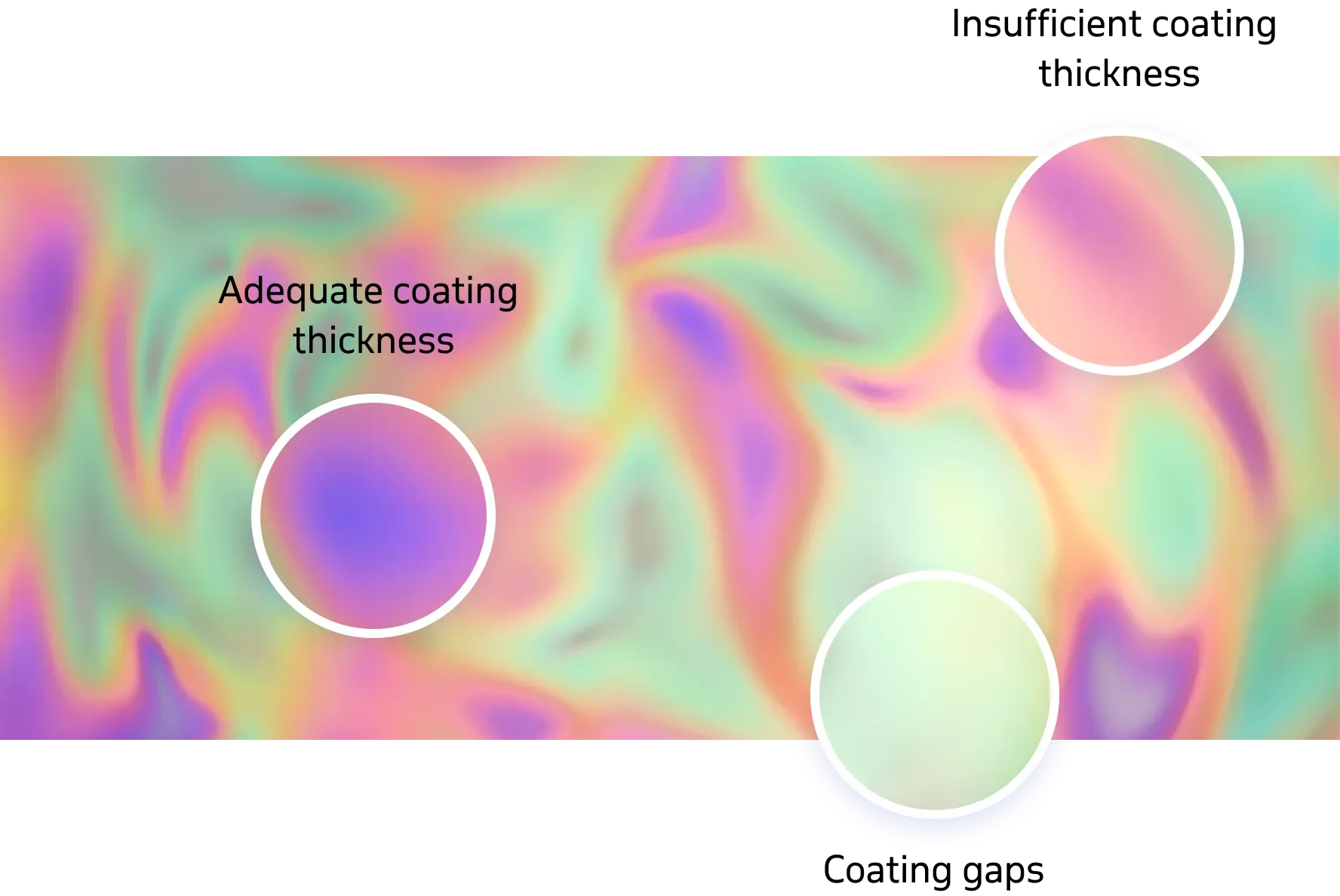

The delivered AI solution automatically performs the following defect detection tasks:

We rolled out the AI solution to the customer’s on-premises environment to ensure it works without interruption regardless of the internet connection and enables real-time defect detection. Post-deployment, our team monitored the solution to prevent model drift and collaborated with the customer’s production and IT teams to develop new features, enhance the solution’s detection capabilities, and provide ongoing advisory support.

Itransition’s team implemented an on-premises AI defect detection solution, helping the customer achieve 100% inspection without compromising manufacturing speed or increasing the amount of manual labor, which enabled them to:

Service

Itransition offers full-cycle artificial intelligence services to help companies build and scale powerful AI solutions tailored to their business needs.

Service

Rely on Itransition`s AI consulting services to maximize business value from your AI initiative and streamline your artificial intelligence project.

Service

Get ML consulting and development services from machine learning experts. Proven expertise in artificial intelligence, machine learning, and data science.

Service

Explore our range of machine learning consulting services, along with related technologies, use cases, implementation roadmap, and payoffs.

Service

Itransition develops powerful and secure AI software with advanced automation and analytics capabilities to improve operational efficiency and decision-making.

Insights

Discover the methods, benefits, and applications of medical image analysis as well as top medical image analysis tools and AI technologies to choose from.