Services

SERVICES

SOLUTIONS

TECHNOLOGIES

Industries

Insights

TRENDING TOPICS

INDUSTRY-RELATED TOPICS

OUR EXPERTS

January 22, 2026

Manufacturing digital twins operate in a continuous loop cycle, with the virtual twin continuously mirroring the physical asset’s state and behavior and serving as a basis for production teams to control and optimize operations. This requires a combination of components:

Digital twin technology can prove highly valuable from the early stages of the product lifecycle, with engineers using it to build virtual prototypes that replicate a physical product's function, form, and behavior, simulating its performance and manufacturability under real-world conditions. This involves, for instance, running thousands of virtual "what-if" scenario simulations, including extreme heat or heavy loads, to assess the product's stress tolerance and identify potential issues instead of performing complex tests with actual prototypes in the physical world.

Minimizing the need for expensive and time-consuming testing iterations with physical prototypes, thus speeding up the product development process.

In addition to identifying product flaws during the design stage, digital twins can also be useful for detecting defects at the assembly stage. IoT sensors across the production line, including high-resolution cameras and CMMs, collect information on critical metrics (component dimensions, weld integrity, etc.) and stream it to the platform hosting the digital twin. The digital twin simulates changes based on the previously received data, with any deviation from expected parameters promptly flagged to the operator. The use of digital twins in product quality management also simplifies root cause analysis, as engineers can identify potential causes for specific defects, such as a worn mold, based on the source of deviating parameters.

Shifting product quality assurance from reactive inspection to more cost-efficient defect prevention, thereby reducing waste and material costs for rework.

Another popular use case involves using digital twin technology as virtual representations of specific manufacturing equipment, such as a pump or a mechanical arm, to spot anomalous equipment performance and conditions. IoT sensors collect real-time data on equipment temperature, vibration, acoustic emissions, and other metrics so that the digital twin can mirror the machine’s behavior, with any abnormalities in operation immediately visible. Additionally, manufacturing predictive analytics software powered by machine learning models can process this information to identify outliers that can be a sign of degradation, forecast the likelihood and timing of component failure, and trigger a maintenance request if needed.

Enabling proactive and timing maintenance initiatives to minimize the risk of unplanned downtime and extend the equipment lifespan.

Digital twins are often deployed at scale, serving as virtual replicas of an entire production line, manufacturing cell, or even a factory. This way, the technology helps companies get a high-level overview of their large, integrated production systems and track manufacturing processes end-to-end to identify bottlenecks and areas for improvement. Such digital twins also enable manufacturers to simulate and validate potential process adjustments, such as changes in production scheduling or facility layout, predicting their impact on production processes before implementing them. Supply chain changes and new logistics scenarios can be simulated the same way to optimize operations and validate their readiness for various disruptions.

Streamlining manufacturing operations to maximize production output while minimizing energy consumption for greater sustainability.

Digital twins are excellent workforce development tools, allowing companies to train their employees in a highly realistic but risk-free virtual environment. Combined with AR and VR technology, digital twins simulate workplace scenarios where new operators, maintenance staff, and other trainees can safely interact with virtual machinery and thus practice their tasks.

Enabling new hires to train on high-risk equipment without safety and process disruption concerns.

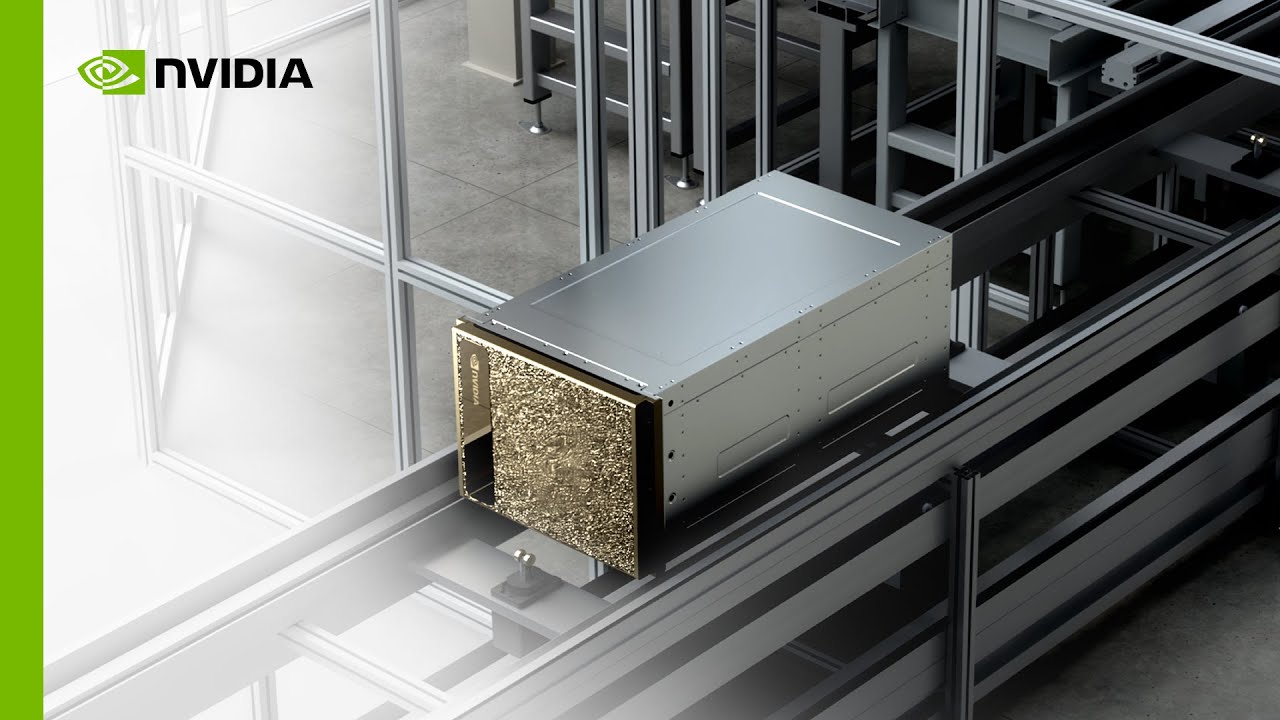

Taiwan-based electronics manufacturer Wistron built digital twins replicating its factories for the production of NVIDIA's high-performance computing hardware. Developed in partnership with NVIDIA, these digital twin solutions enable Wistron to monitor manufacturing operations in real time, as well as to test new factory layouts in a physically accurate digital environment. The company has already achieved a 50% reduction in end-to-end production times and a 40% cut in defect rates thanks to implementing the digital twin technology.

French automotive manufacturer Renault heavily relies on the digital twin technology in its product development workflows. First, designers create a digital twin model of the future vehicle's exterior and interior to assess its potential look and perceived quality. The engineering team then adds the engine, circuitry, and other virtual components to create a highly accurate 3D replica of the entire vehicle. This model then can be used for multiple types of virtual tests, including bodywork aerodynamics, engine performance, and on-board safety testing.

German manufacturer of production machinery HELLER partnered with Siemens to implement a digital twin solution for product design optimization. HELLER leveraged the digital twin to enhance the design of an existing combustion engine’s transmission case, making it more suitable for an electric vehicle. The development team tested new configurations via a virtual model and implemented these changes in its physical counterpart, achieving reduced vibration, weight, and noise.

Before large-scale implementation, launch a pilot program of your digital twin initiative, targeting a limited set of high-value use cases, like specific business units or products. This will help ensure the return on initial investment and stakeholder buy-in.

Whenever possible, adopt devices and software for your digital twin solution that comply with major interoperability standards, such as OPC UA. These provide common communication protocols and data formats to ensure seamless information exchange between the different components of the digital twin.

Implement robust protection mechanisms to ensure secure data storage and transmission across the digital twin components, with a focus on edge devices like IoT sensors. These measures can include firewalls, data encryption, and IoT device authentication via X.509 digital certificates.

Our consultants assist you with key aspects of your manufacturing software initiative, including business needs analysis, development, and user onboarding, to make sure that the solution delivered fully meets your expectations.

Our team handles your manufacturing software implementation project end-to-end, taking care of solution design and development, system integration, and post-release support and maintenance.

The Internet of Things, machine learning-powered analytics, and robotics-enabled automation are just some of the technologies that have fueled the rise of smart manufacturing or “Industry 4.0” in recent years, and digital twins combine all of them into powerful and highly integrated solutions.

From easier prototyping to optimized production scheduling and proactive maintenance, digital twins will help address the well-known productivity stagnation affecting this sector. To leverage these capabilities, implement tailored manufacturing software solutions with an experienced IT partner like Itransition.

In the manufacturing industry, digital twins are usually classified by their scope and the scale of what they replicate.

Traditional simulations are essentially static, since they replicate a specific event based on historical data. Digital twins, on the other hand, offer a dynamic representation of a real-world scenario, constantly updated with real-time data. Furthermore, digital twins have a two-way connection with their physical counterpart, as they receive data from it but can also control it.

Insights

Discover how IoT can help manufacturers optimize supply chains, energy management, enhance inventory management, improve product performance, and boost revenue.

Insights

Learn how machine learning can help manufacturers to improve operational efficiency, discover real-life examples, and learn when and how to implement it.

Insights

Learn how to leverage computer vision in manufacturing and explore its use cases, adoption challenges, and implementation guidelines.

Insights

How to achieve unfailing IIoT security? Explore the most common threats and develop a feasible strategy to effectively overcome them.

Insights

Learn how AI-driven automated visual inspection systems help manufacturers in different industries improve quality control and decrease operational costs.

Service

BI can bring multiple benefits to the manufacturing industry. Explore manufacturing BI use cases and get tips on tool selection and implementation.