Services

SERVICES

SOLUTIONS

TECHNOLOGIES

Industries

Insights

TRENDING TOPICS

INDUSTRY-RELATED TOPICS

OUR EXPERTS

August 12, 2025

Scheme title: Internet of Things in logistics market from 2025 to 2030

Data source: Research and Markets

forecasted IoT in logistics market in 2032

the CAGR of the IoT in the logistics market from 2025-2030

Logistics companies leverage IoT solutions for the ongoing monitoring of shipment location throughout the entire supply chain. Moreover, IoT sensors record the shipment’s geolocation and its transportation environment’s temperature and humidity, so companies can quickly spot violations of storage conditions or unauthorized access. This helps reduce loss and damage of shipments and prevents tampering or theft during transportation.

IoT solutions complemented with GPS tracking and telematics technologies give logistics companies real-time visibility into key vehicle parameters, such as speed, technical condition, fuel level, and operating modes. Using this data, companies can quickly detect inefficiencies in a vehicle’s performance, like engine overheating or excessive fuel consumption, and take measures to fix them. Thus, companies can schedule timely vehicle maintenance, reducing fuel and labor costs and achieving more efficient fleet management.

The use of IoT devices, such as sensors, GPS trackers, and RFID tags, in warehouses allows logistics companies to obtain accurate data on their inventory levels and product movement, keeping track of where a particular item is located and its current condition or how much of a certain product remains in the warehouse at any time. This simplifies warehouse operations and allows companies to replenish stock levels in a timely manner, and quickly identify product damage.

Another widespread use of IoT in logistics is to equip vehicles with IoT devices that track traffic parameters, the current location and technical condition of the vehicle, weather changes, and the situation on the road. By leveraging this data, logistics companies can efficiently tailor routes based on current road and vehicle conditions and delivery specifics, avoid unexpected delays, and reduce carbon emissions, thereby improving delivery times and lowering costs.

IoT sensors help companies keep track of how well vehicles are performing, collecting data on their temperature, wear and tear, energy consumption, and other essential metrics. This enables logistics companies to plan equipment maintenance in advance, avoiding costly repairs, downtime and extending the machinery's lifecycle. Also, if something goes wrong, the IoT system can signal potential problems to prompt logistics managers to take immediate action.

Connected devices placed in trucks and warehouses can continuously monitor the storage conditions of temperature-sensitive products like fresh produce and medications, including temperature, humidity, and vibration levels to detect any deviations from established norms. These actionable insights help companies prevent problems like product spoilage or regulatory violations.

Itransition helped a startup develop a mobile application for managing contactless delivery of goods using drones. The app allows users to set a landing zone for delivery using their location data or photos of the area, while operators can track the route and manually control the drone's flight, taking into account obstacles on the ground for better delivery. The application also features built-in analytics that enables the collection and processing of data to optimize delivery processes and enhance the reliability and accuracy of future operations.

Amazon uses more than 750,000 automated robots in its logistics centers, which creates one of the most

powerful smart logistics ecosystems. After the purchase of the robotics company Kiva Systems in 2012,

Amazon introduced the first Kiva mobile robots. The company now utilizes a variety of other types of

robotics, including manipulators for packing, sorting, and placing goods, as well as autonomous

transportation platforms.

Each robot is equipped with IoT sensors, cameras, and navigation

systems that allow employees to monitor their location, technical status (battery charge and issues), and

operational workload in real time. These IoT-based robots enable Amazon to significantly enhance the

efficiency of their logistics processes, making workplaces more productive, safe, and efficient for

employees.

Image title: Amazon robotics for automating inventory management

Image source: Amazon

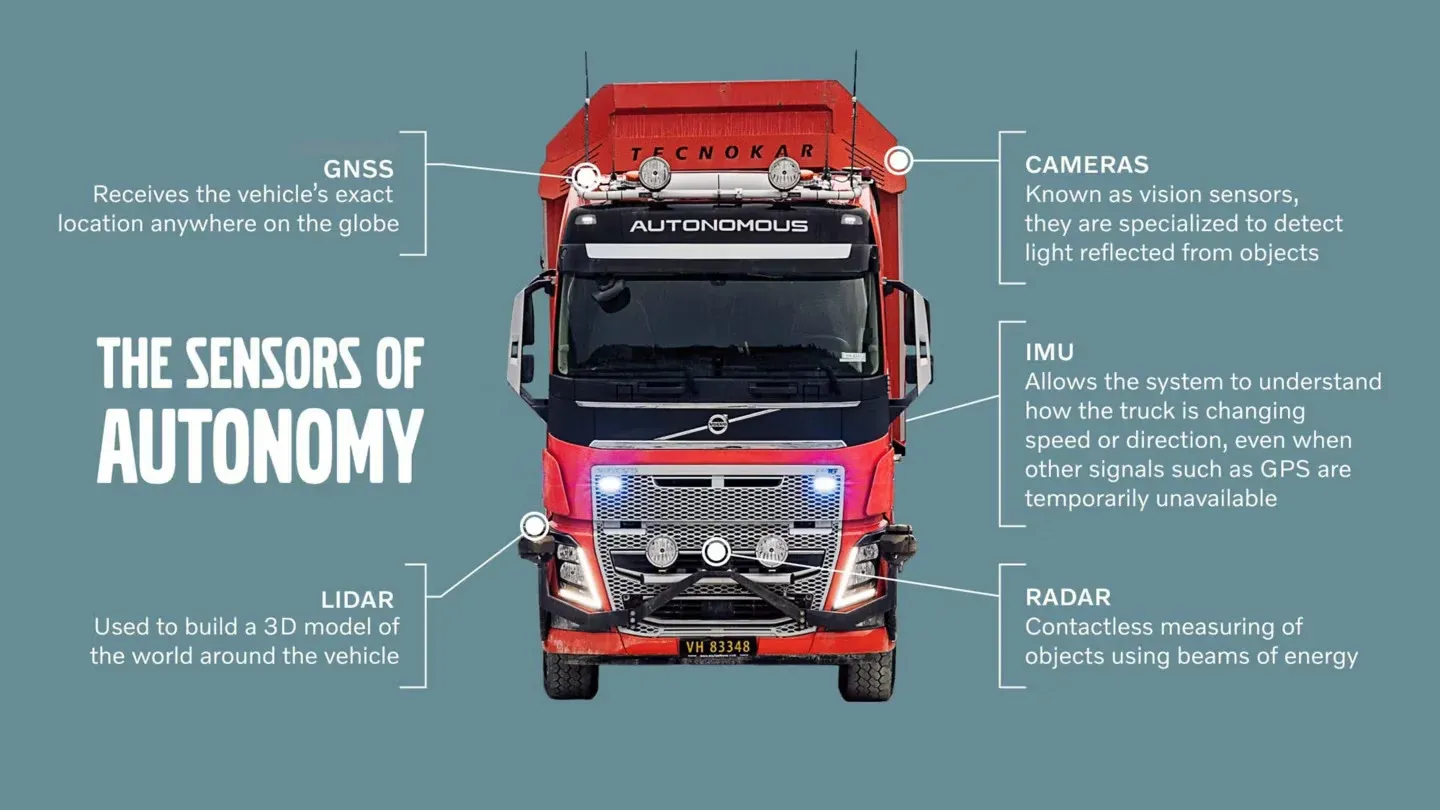

Volvo created autonomous trucks that can operate safely in different weather conditions. They are

equipped with high-precision IoT sensors, including cameras, radar, lidar, microphones, and satellite

navigation systems, and software which is configured based on the conditions in which the truck is

expected to operate. Moreover, the truck’s vital systems are duplicated to ensure it continues to run

safely even if something breaks.

The technology is improving rapidly and has already proven

to dramatically enhance road safety for drivers and reduce accidents in various weather conditions.

Autonomous trucking is more than an evolution - it creates a new value proposition, redefining how goods are transported across supply chains.

Image title: Autonomous trucks fitted with IoT sensors

Image source: Volvo

One of DHL’s most significant IoT initiatives is the SmartSensor system which tracks the exact location of

shipments at every stage of their journey and monitors their critical environmental parameters, like

temperature, humidity, impact, and light, especially vital for the pharmaceutical and medical sectors. The

system immediately notifies operators of any deviations from the established norms to take action.

This way, the SmartSensor system helps DHL timely identify and prevent risks associated with the

damage of sensitive goods and increase partners’ and customers’ trust.

Image title: SmartSensor system for real-time shipment tracking

Image source: DHL

The IoT ecosystem allows logistics providers to keep a better track of their workflows by collecting real-time data on the condition and storage of shipments, equipment, and vehicle operations. This provides companies with total control over their logistics operations, makes decision-making faster, and reduces risks and losses.

IoT helps reduce transportation, storage, and handling costs by automating various logistics operations such as cargo tracking, inventory tracking, route planning, and fuel consumption control. With the help of IoT-generated data, logistics companies can also accurately predict when maintenance of machines and vehicles is needed, reducing repair costs and unplanned breakdowns.

IoT-enabled systems handle simple, routine daily tasks without human involvement, including store shipments logging, climate conditions monitoring, and warehouse records management, enhancing employee productivity.

Real-time monitoring of transportation, warehouses, and equipment with the help of IoT enables companies to manage assets and resources more effectively. IoT-generated data also helps logistics companies identify unused or overloaded vehicles, as well as track their conditions, perform timely maintenance, and extend its life, which also helps reduce operating costs.

With IoT, logistics companies can monitor truck technical conditions in real-time, analyze driver behavior, and navigate potential issues on the road. Based on IoT data, logistics companies can also timely notify the driver of possible threats on the road or traffic jams, as well as warn them of the need to take a break.

Using predictive analytics and real-time IoT-generated data on routes, goods, traffic, and vehicle location, logistics companies can timely respond to unexpected delays, route changes, and other emergencies or prevent them entirely. This not only helps to preserve product quality and maintain a more stable delivery schedule, but also improves customer experience.

Based on the IoT history of recent years, Internet of Things technology has transformed logistics, making supply chain operations more transparent and efficient. Given how quickly the business landscape is changing, moving towards process automation and optimization, the role of IoT in logistics will only grow in the future. What is more, IoT is going to be increasingly integrated with other emerging technologies that will enable even more accurate shipment and vehicle tracking, route optimization, and forecasting customer expectations.

Logistics companies increasingly implement autonomous cars, trucks, or drones to increase delivery speeds

and reduce transportation costs by minimizing human interaction. As consumer expectations for speed and

visibility of delivery increase, autonomous vehicles are expected to become increasingly ubiquitous,

particularly among logistics companies seeking to gain a competitive edge.

IoT technology is the

key part of such systems, collecting and transmitting real-time data on routes, road conditions, cargo

status, and the technical condition of the vehicle itself to cloud platforms.

| The drone delivery service market is expected to grow rapidly in the next decade. By 2035, it is projected to reach $16.07 billion with a CAGR of 32.7% | |

|---|---|

| In 2025, the size of the autonomous trucks market will reach $42.9 billion, and by 2032, it is expected to almost double to $86.8 billion | |

| The market of autonomous vehicles will reach $428 billion by 2025, with the shipments and passenger transportation segment accounting for about 65% | |

| By 2035, the largest autonomous trucking market shares will come from China ($327 billion), the US ($178 billion), and Europe ($112 billion) |

United States

USA leads AD truck adoption thanks to strong TCO benefits, significant driver shortages and long freight distances

Europe

Europe sees high TCO benefits but faces slower adoption due to cross-border regulatory hurdles and operational complexity

China

China lags in adoption due to lower TCO benefits and higher upfront investment.

Adoption could

follow a similar speed to USA and Europe if the government chooses to prioritize it

Scheme title: Predicted share of autonomous trucks from 2025 to 2035 by region and usage scenario

Data source: Boston Consulting Group

Since IoT devices generate massive amounts of data, processing it is a challenging task. The use of AI-enabled analytics tools enables logistics companies to more accurately and rapidly analyze data for demand forecasting, logistics optimization, energy savings, equipment failure detection, and inventory management automation. Logistics companies that have already integrated AI into their business processes adapt faster to market changes and scale more easily, especially in the face of volatility and growing customer expectations for speed, personalization, and service quality.

| Uber Freight began actively applying artificial intelligence technologies to optimize delivery routes, reducing the number of empty trips by about 10-15%, which, in turn, helped reduce logistics costs and improve overall efficiency | |

|---|---|

| The implementation of AI-based solutions helps to reduce transportation costs by 5-10%, increases the accuracy and reliability of delivery by 20%, and provides an overall reduction in logistics costs by up to 15% | |

| The artificial intelligence in logistics market size is valued at $26.35 billion in 2025 and expected to grow to $707.75 billion by 2034 |

Scheme title: Market size of AI-technologies in logistics from 2024 to 2034

Data source: Precedence Research

| The AI market in the US logistics sector is projected to reach around $242.43 billion by 2034 with a CAGR of 44.69% from 2025 to 2034 |

|---|

Scheme title: Artificial intelligence market in the US logistics sector 2024 to 2034

Data source: Precedence Research

Scheme title: The market share of AI technologies in supply chain and logistics in 2024

Data source: Global Market Insights

A 5G network enables almost instant data transfer with minimal latency, which is especially important for

logistics Internet of Things systems, where sensors, cars, and drones need to exchange information quickly and

consistently. In logistics, such technology also enables more accurate management of autonomous vehicles,

drones, and robotic systems.

Furthermore, 5G provides high reliability connection since it supports

mass device connectivity, providing companies with better equipment control and more efficient delivery

without the risk of overloading the network.

| The private 5G networks market size will reach $4.9 billion in 2025, and will grow at a 40% annual rate to $102.5 billion by 2034 | |

|---|---|

| The 5G transport market, valued at $50 billion in 2025, is projected to reach $150 billion by 2033, growing at a 15% CAGR from 2025 to 2033 |

Scheme title: 5G transportation networks market growth from 2025-2033

Data source: Data Insights Market

Scheme title: Key leading players in 5G transport networks in 2025

Data source: Data Insights Market

Scheme title: Geographical distribution of 5G transport network development in 2025

Data source: Data Insights Market

LPWAN networks enable logistics companies to transmit IoT data over long distances with minimal power consumption, which is particularly important when monitoring shipments in warehouses, ports, and along delivery routes. These networks enable stable transmission of critical IoT data even when the signal is weak. What is more, LPWAN can scale easily without the need for an expensive telecommunications infrastructure, which makes LPWANs an excellent solution for building cost-effective supply chain monitoring and management systems.

| LoRaWAN remains dominant in the private network market, especially popular in the sector of asset and fleet tracking in logistics | |

|---|---|

| The global LPWAN market size reached $48.67 billion in 2025 and will reach $395.55 billion by 2030, growing at a CAGR of 52.05% between 2025 and 2030 |

Scheme title: The size of the LPWAN market between 2025 and 2030

Data source: Mordor Intelligence

70+ countries

Image title: Coverage map of LPWAN technologies

Data source: DHL

58+ countries

Image title: Coverage map of LPWAN technologies

Data source: DHL

157+ countries

Image title: Coverage map of LPWAN technologies

Data source: DHL

Blockchain and IoT go hand in hand, since blockchain helps guarantee the security, transparency, and accuracy of IoT-generated data. Such synergy is advantageous within the supply chain process, which usually involves a lot of parties like manufacturers, carriers, warehouses, customs, and retailers, as everyone has access to the same verified data, thereby eliminating the risk of tampering, information loss, or unauthorized access.

Blockchain-based smart contracts are also increasingly used to automate delivery confirmation, payment execution, and paperwork during the transportation of goods. Their popularity is due to the fact that they simplify documents processing, reduce human-made mistakes, and speed up transactions by reducing the number of parties through which they must pass. Thus, the integration of IoT with blockchain is expected to further enhance supply chain visibility, security, and transparency.

| By 2034, the global blockchain in supply chain market is expected to grow to an impressive $95.3 billion, a sharp jump from $3.5 billion in 2025 with a CAGR of 44.5% |

|---|

Scheme title: Market size for blockchain supply chains by size and component between

2025 and 2034 Source: Market.us

| The market size of blockchain in the supply chain sector in the US reached $1.1 billion in 2025 and is anticipated to grow to $39.9 billion by 2034 with a CAGR of 48.6% |

|---|

Scheme title: The market size of blockchain in the supply chain sector in the US between 2024 and 2034

Data source: Market.us

Scheme title: Global market of blockchain supply chain by region (2025-2033)

Data source: Data Insights Market

The adoption of IoT technology in logistics can be associated with a number of issues that can make companies reluctant to adopt it.

Challenge | Solution | |

|---|---|---|

Integration with the existing systems |

Many logistics companies already have ERP, WMS, and other business software, so integrating new IoT

solutions with these existing ones can be challenging due to incompatibility between different platforms

and outdated hardware and software that don’t support modern data transfer protocols and interoperability

standards.

| To integrate IoT into existing IT infrastructure as smoothly as possible, logistics companies can use the following practices:

|

Scalability limitations |

With the proliferation of IoT devices and logistics processes, the volume of data is increasing

significantly. Over time, companies can find it challenging to process, store, and analyze it, which can

lead to operational disruptions, data loss, and increased IT infrastructure development costs.

| To successfully scale connected logistics systems, companies must adhere to the following practices when planning IoT architecture:

|

Lack of qualified specialists |

IoT requires highly qualified specialists who are not only proficient in IT but also knowledgeable about

logistics processes, analytics, artificial intelligence, and cloud platforms. The lack of such specialists

in place hinders IoT adoption in logistics, reduces its efficiency, and increases the risk of errors.

| To overcome the lack of skilled IoT professionals, companies can:

|

Data security |

Vulnerabilities in IoT devices can lead to sensitive data breaches, logistical disruptions, and

significant financial losses. In addition, companies must comply with increasingly stringent regulatory

requirements, which require ongoing monitoring, while non-compliance can lead to fines, penalties, and

loss of customer trust.

| A comprehensive approach to IoT system security and compliance is required, which includes the following key measures:

|

We handle the IoT system implementation project end-to-end, including the analysis of current IoT infrastructure, creation of IoT strategy, selection of the tech stack, software development and integration, and post-launch support, helping organizations automate their processes and enhance operational efficiency.

We provide professional IoT consulting services to help companies develop a personalized IoT strategy tailored to their business requirements, budget, and timeline. Our experts begin with an audit of your current infrastructure and guide you throughout the entire project lifecycle, helping you select the best IoT solutions, implement them, and ensure the uninterrupted operation of your IoT solution now and in the future.

The logistics industry is undergoing a major transformation driven by the Internet of Things adoption in

response to the need for faster, more secure and transparent global supply chains, automation to reduce

operating costs, and minimized human errors. By combining the Internet of Things with other emerging

technologies, logistics companies can revamp their workflows, making them more efficient, and deliver

exceptional service to their customers.

However, IoT implementation can bring companies integration,

scalability, and security challenges. To cope with them effectively, companies can turn to experienced IT

vendors like Itransition that specialize in implementing IoT projects of any complexity and in any industry.

Service

Professional IoT development services to deliver IoT solutions that efficiently manage the network of connected devices and generate real-time insights.

Service

Itransition offers IoT consulting services to provide businesses expert guidance through their IoT projects and ensure the solution’s efficiency and high ROI.

Insights

Explore 35 IoT use cases across various industries, top market statistics for 2026, and best practices for IoT adoption.

Insights

Discover recent market statistics on the industrial IoT market state and popular use cases, along with insights into its complementary technologies and benefits.

Insights

Discover how IoT can help manufacturers optimize supply chains, energy management, enhance inventory management, improve product performance, and boost revenue.

Insights

Learn about the use cases, real-life examples, and challenges of the Internet of Things in insurance and how its adoption can optimize your insurance processes.

Insights

Discover common healthcare IoT use cases, benefits, and challenges, how the technology works, and which platforms to consider for medical IoT implementation.

Insights

We explore IoT applications in the automotive industry, describe the most prominent real-life examples, and explain the architecture of connected cars.